Have a ’98 4WD Frontier, 160K miles.

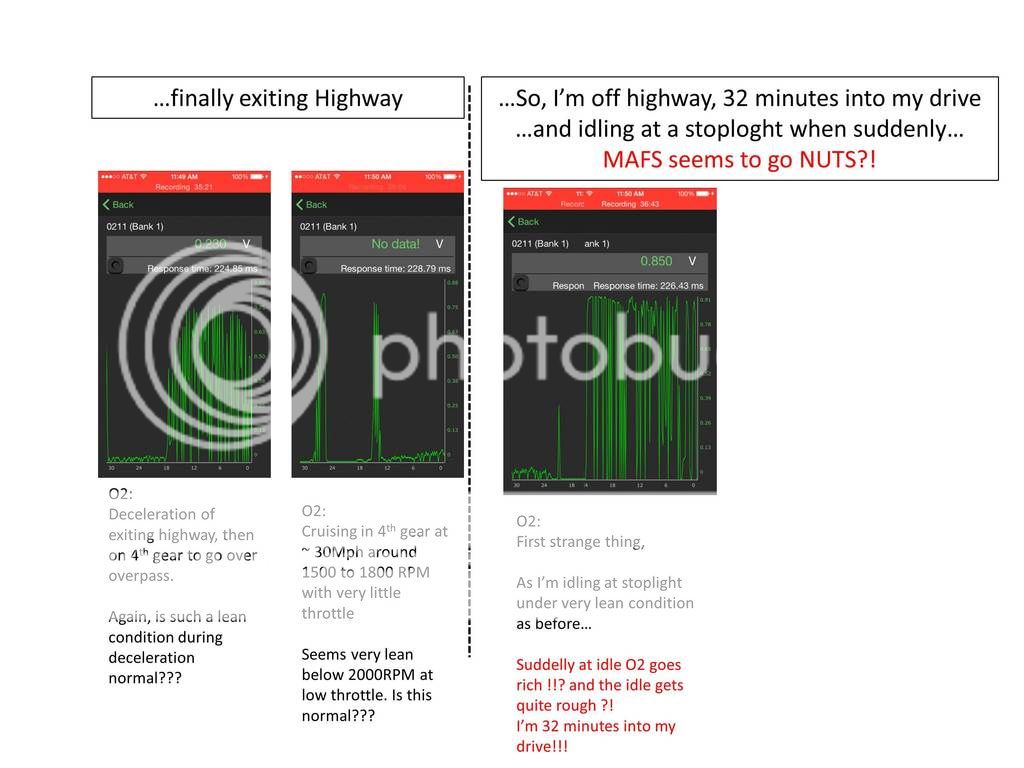

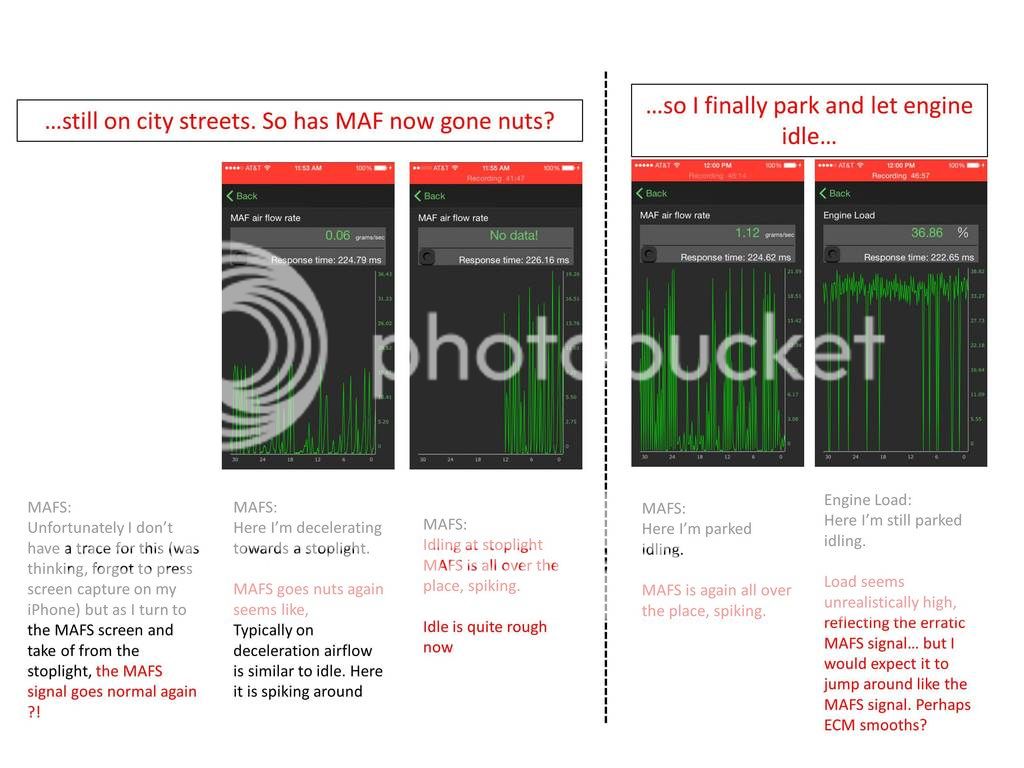

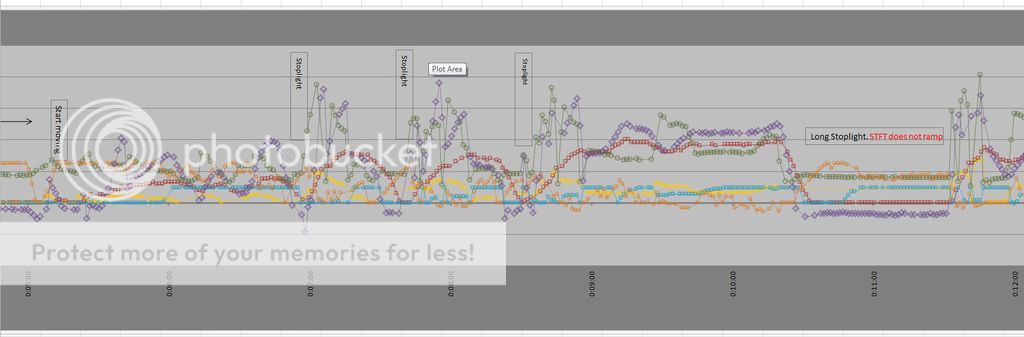

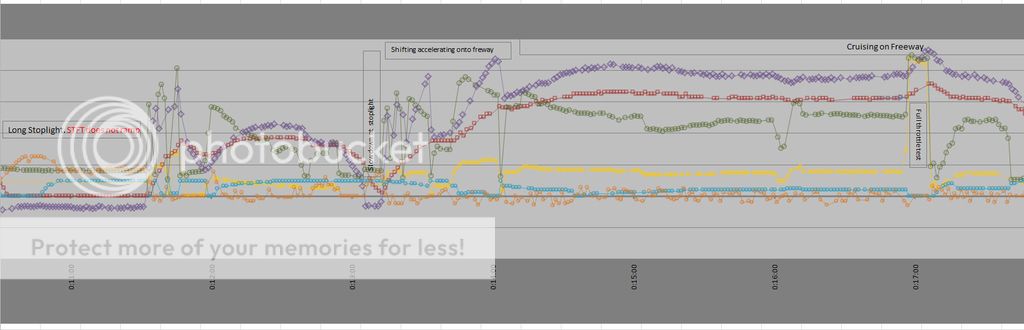

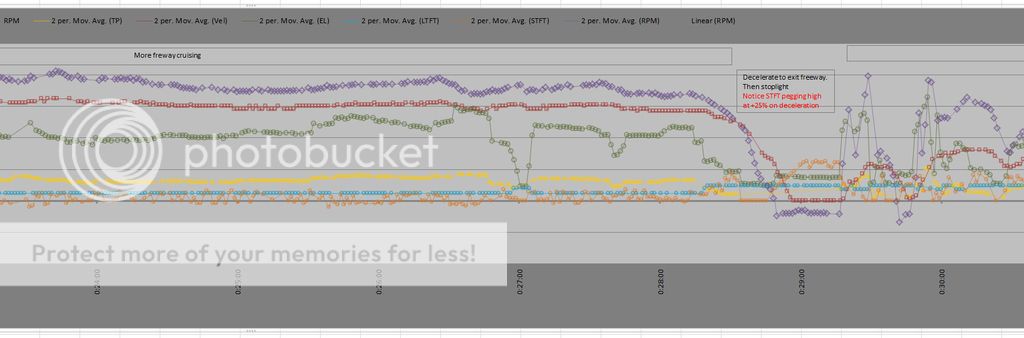

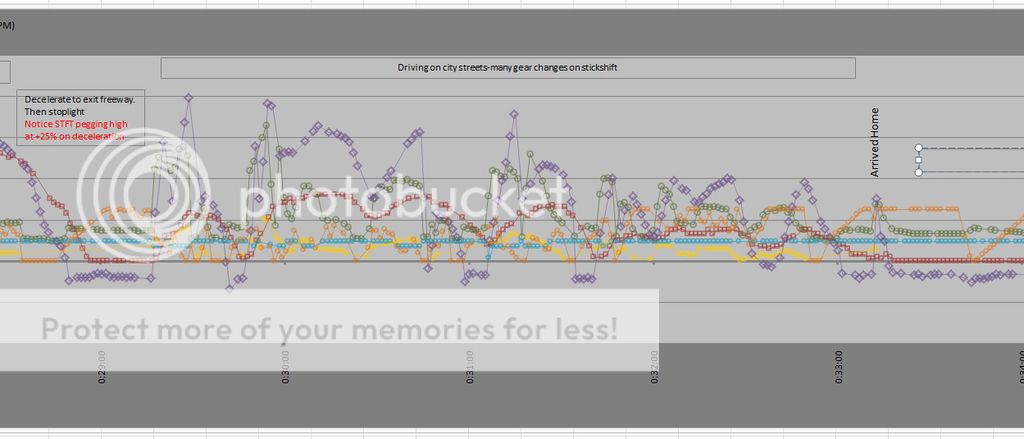

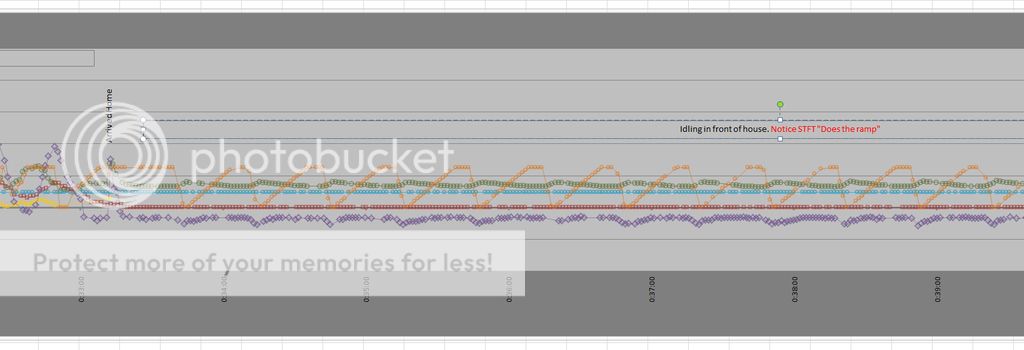

As of 4 days ago I’ve had occasional stalling on idle (perhaps 1 out of 10 times I stop at a stoplight) and also occasional very brief engine hesitations at cruising speeds, akin to a, say, brief “hiccup” in engine power (perhaps a dozen episodes in a 250 mile trip).

It first happened 200 miles away from home on my 4th of July trip. Not a good situation.

No engine light and no codes (I read them).

Concerned about being left stranded, I tried to debug the thing myself since everything was closed for 4th of July. Ended up suspecting the IACV (Idle Air Control Valve) as something that would likely result in this behavior and would also likely not generate a code. But I did not get anywhere. I just sprayed some carburetor cleaner in the throttle air bypass hole, which seemed to make things a little worse, as it seemed to be stalling more often – but it could have been the higher engine temperature too, after repeated starts. Taking apart to clean the IACV was out of the question since I was going to have to remove the throttle body and did not have spare seals to reassemble (seals would likely rip on disassembly after 17 years).

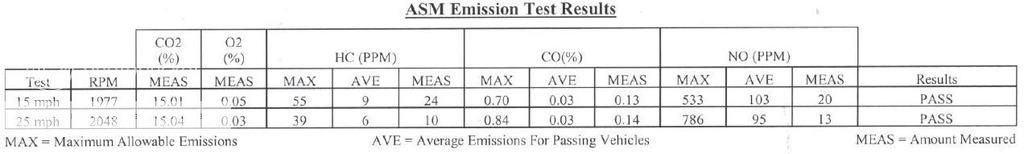

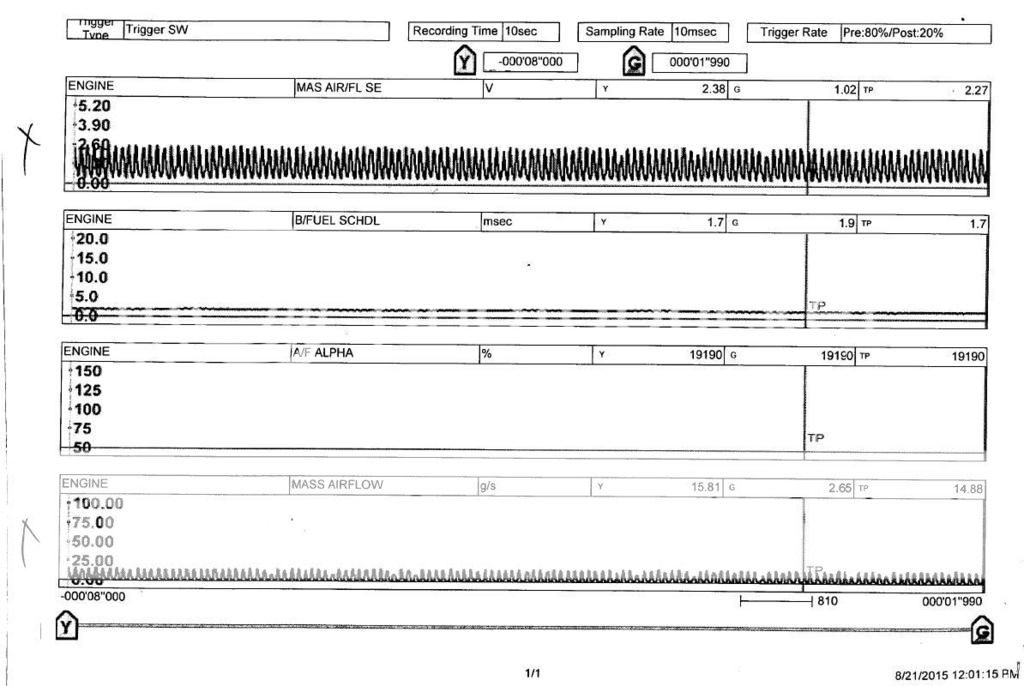

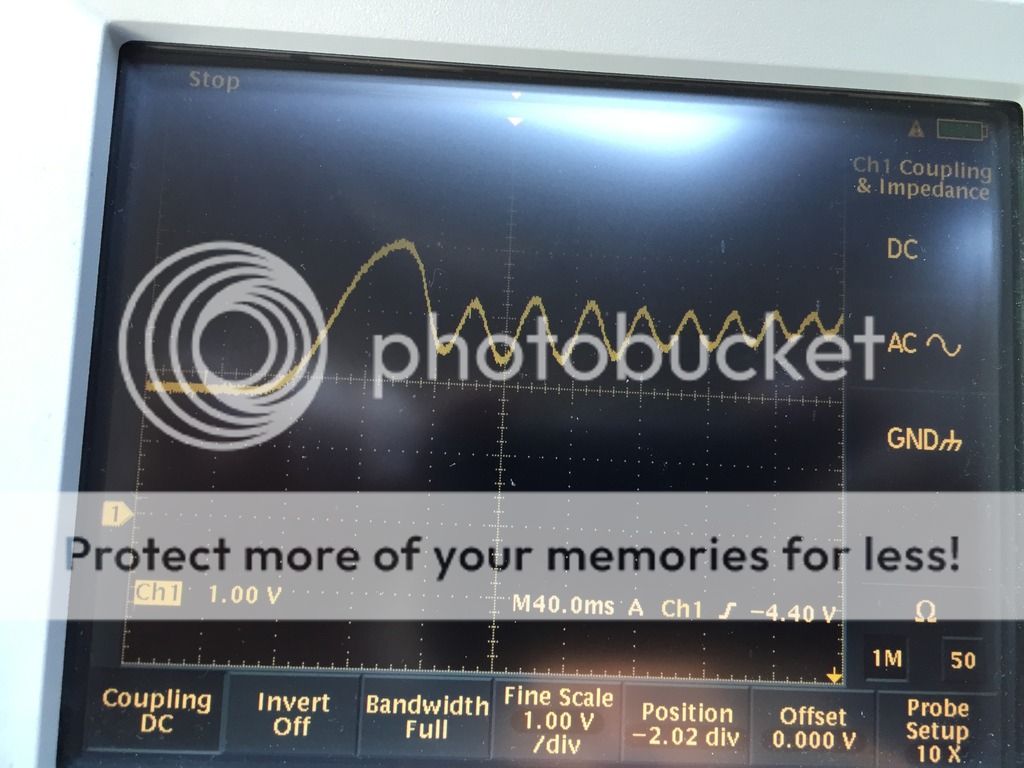

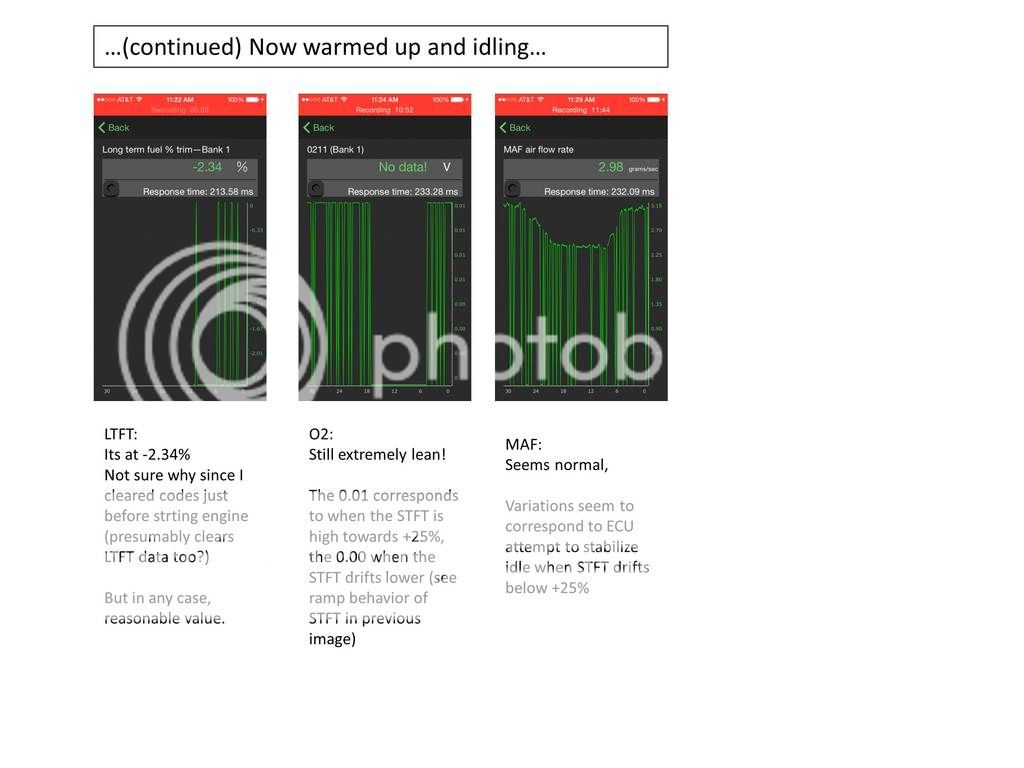

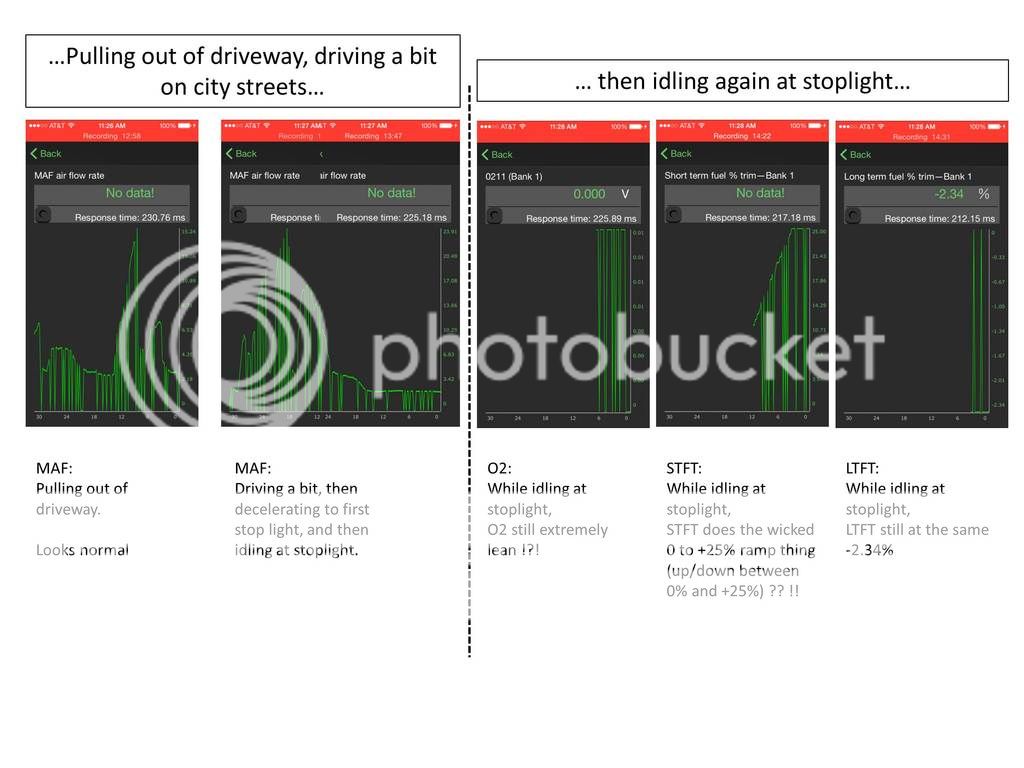

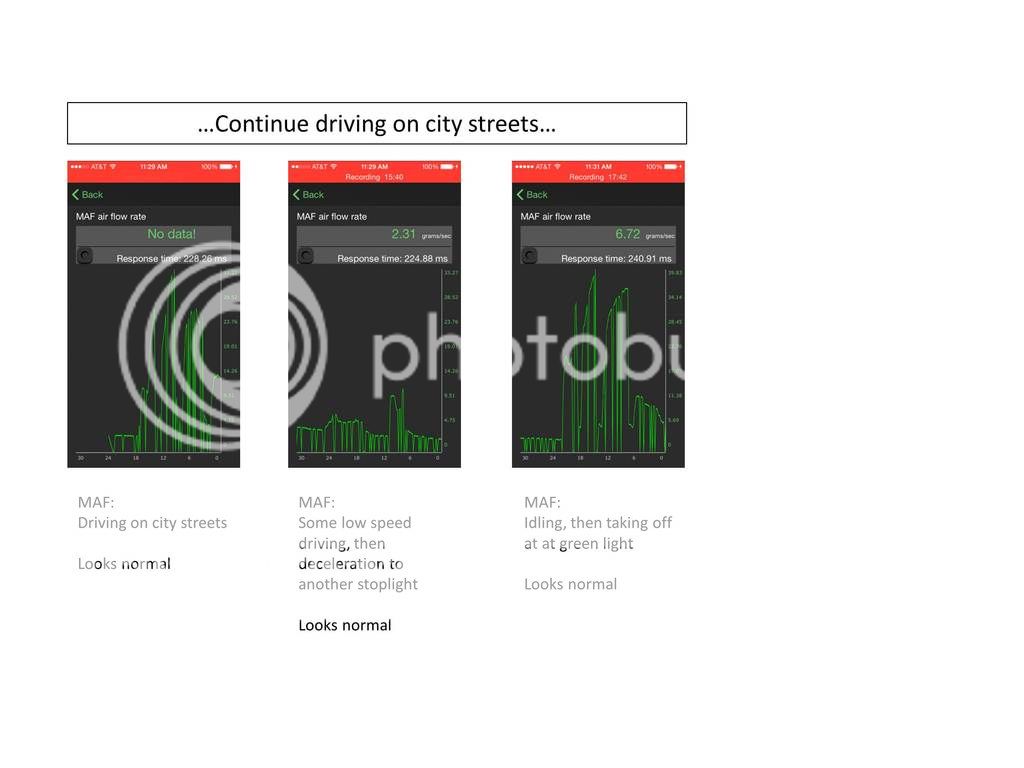

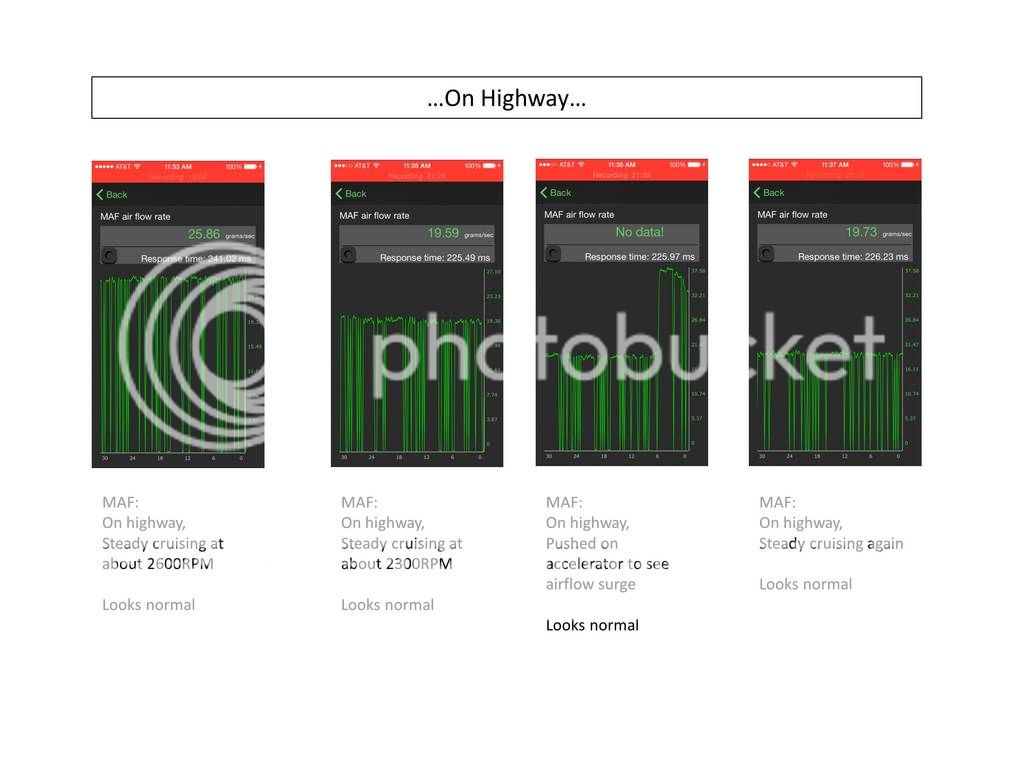

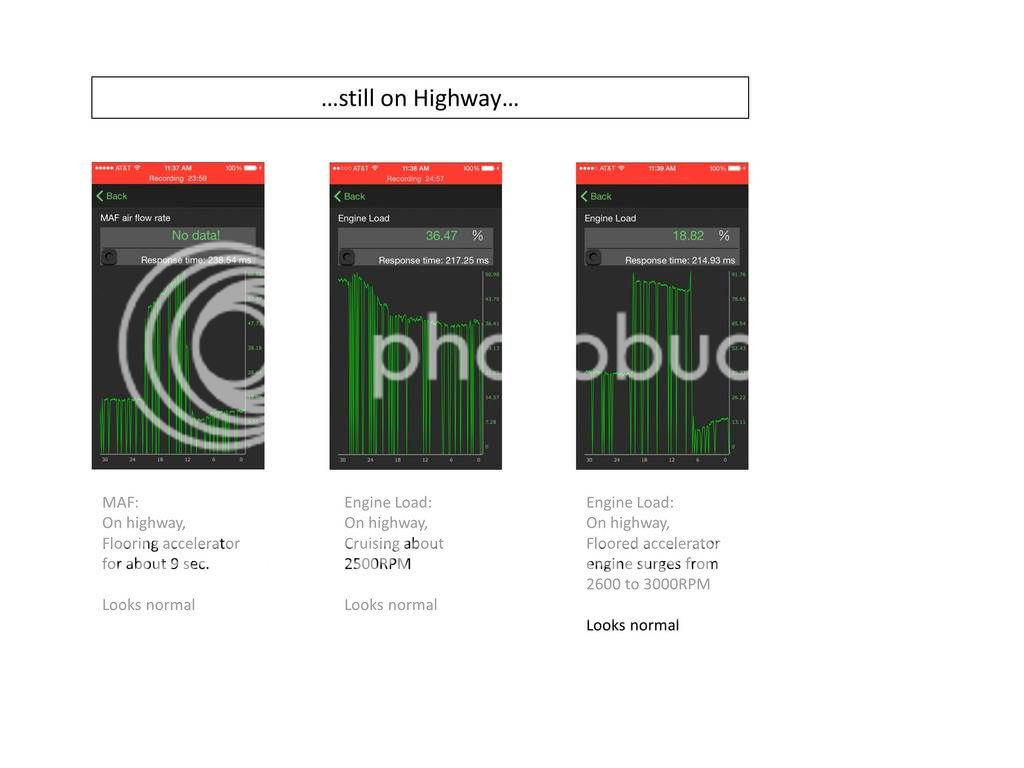

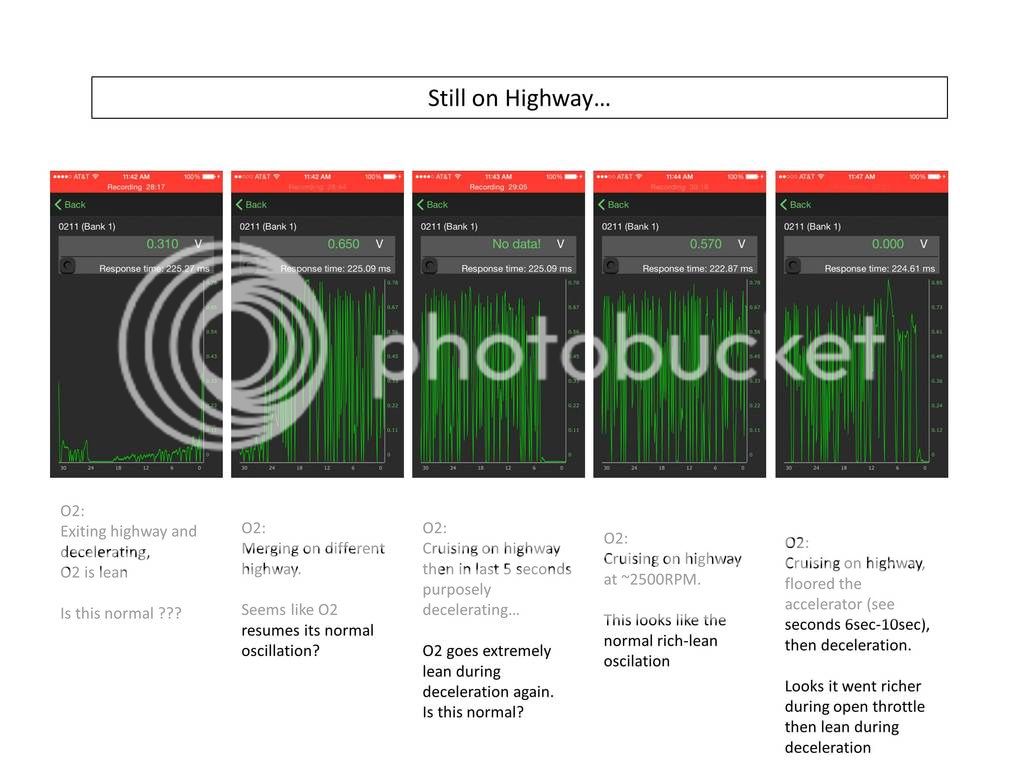

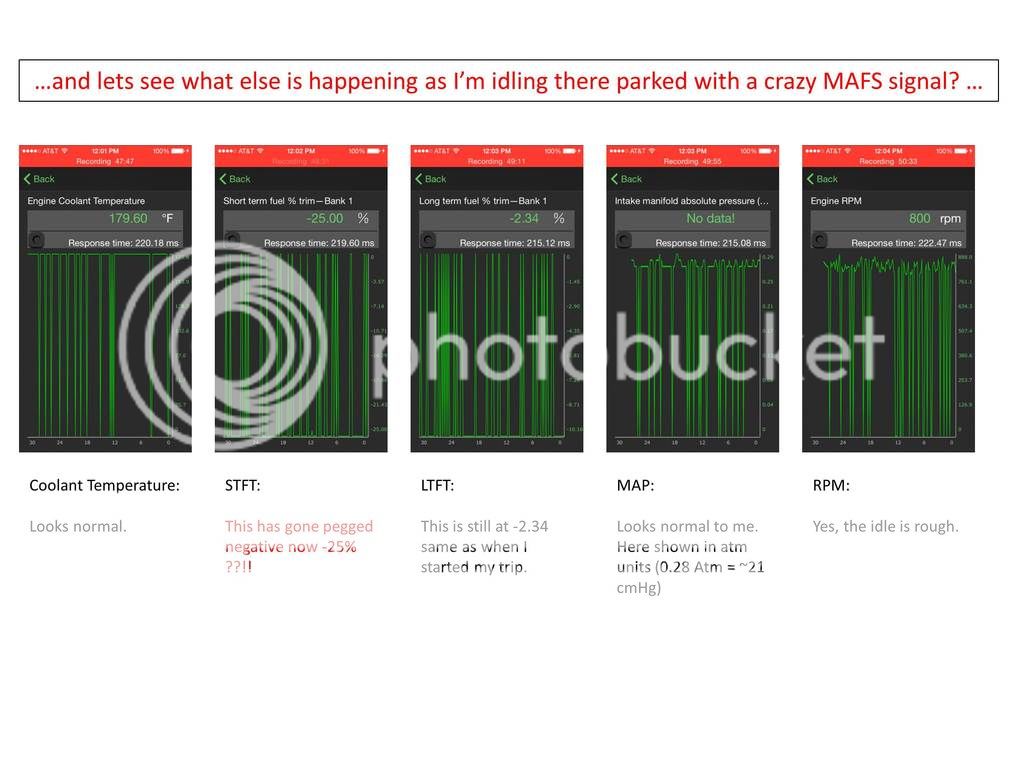

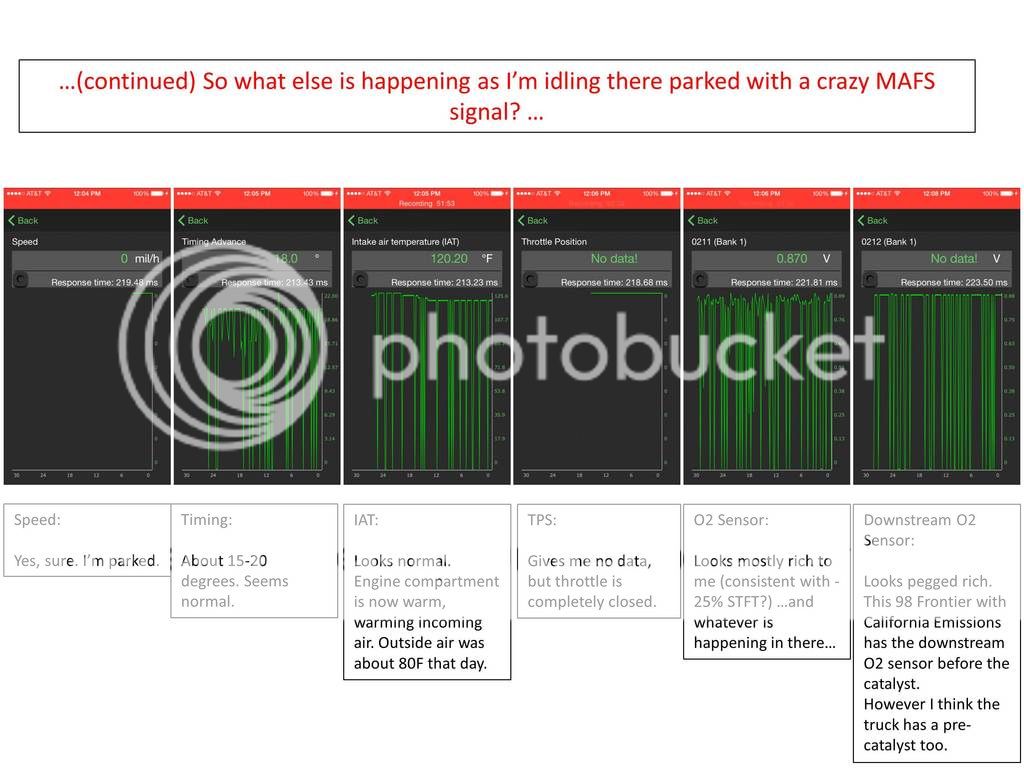

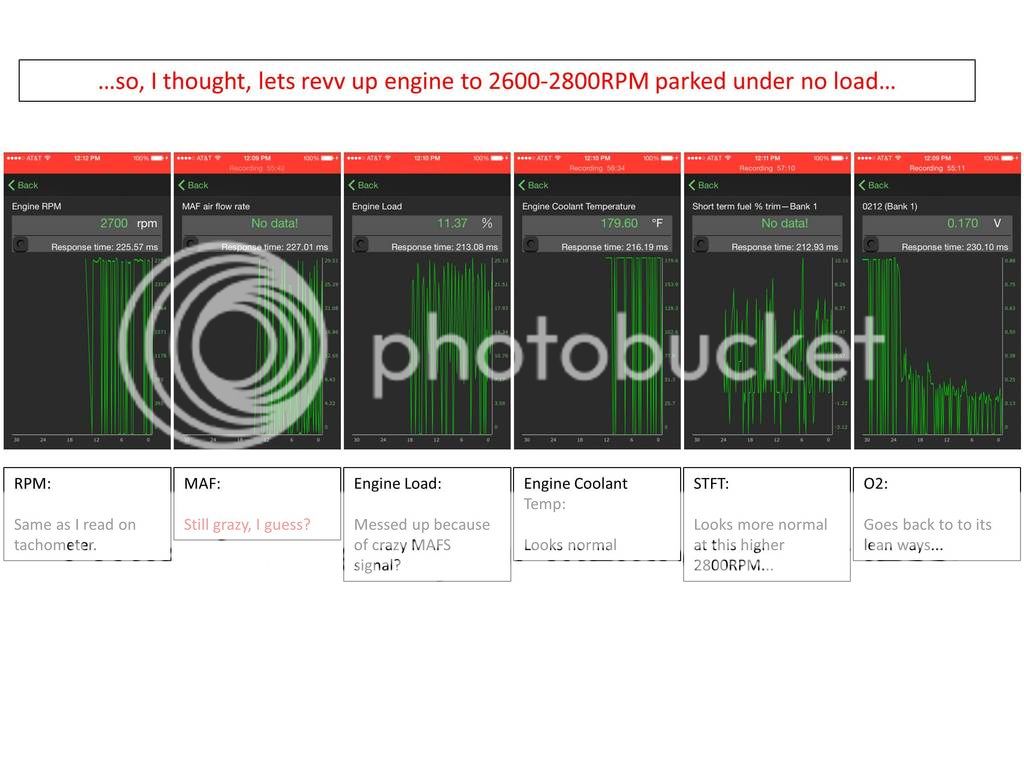

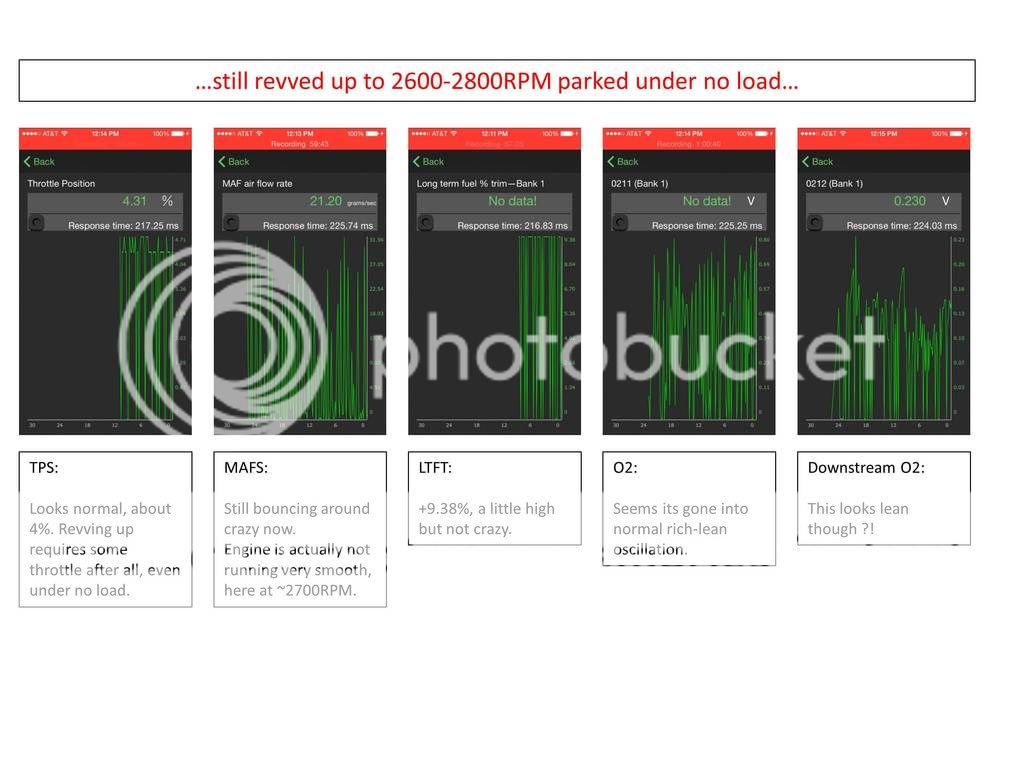

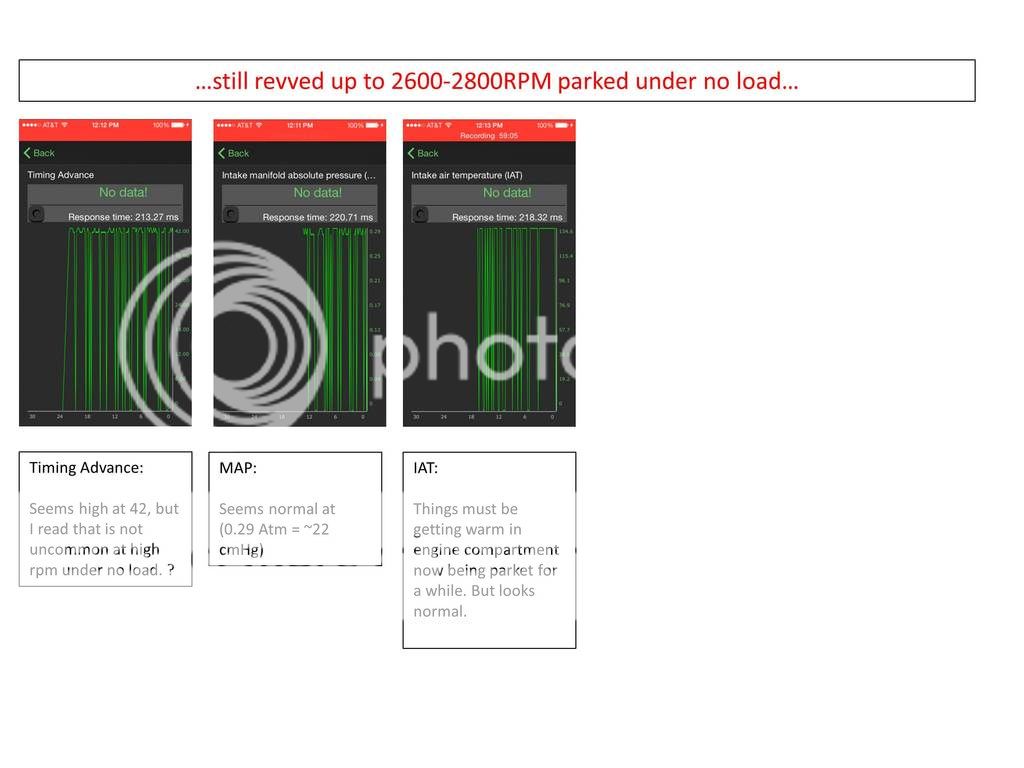

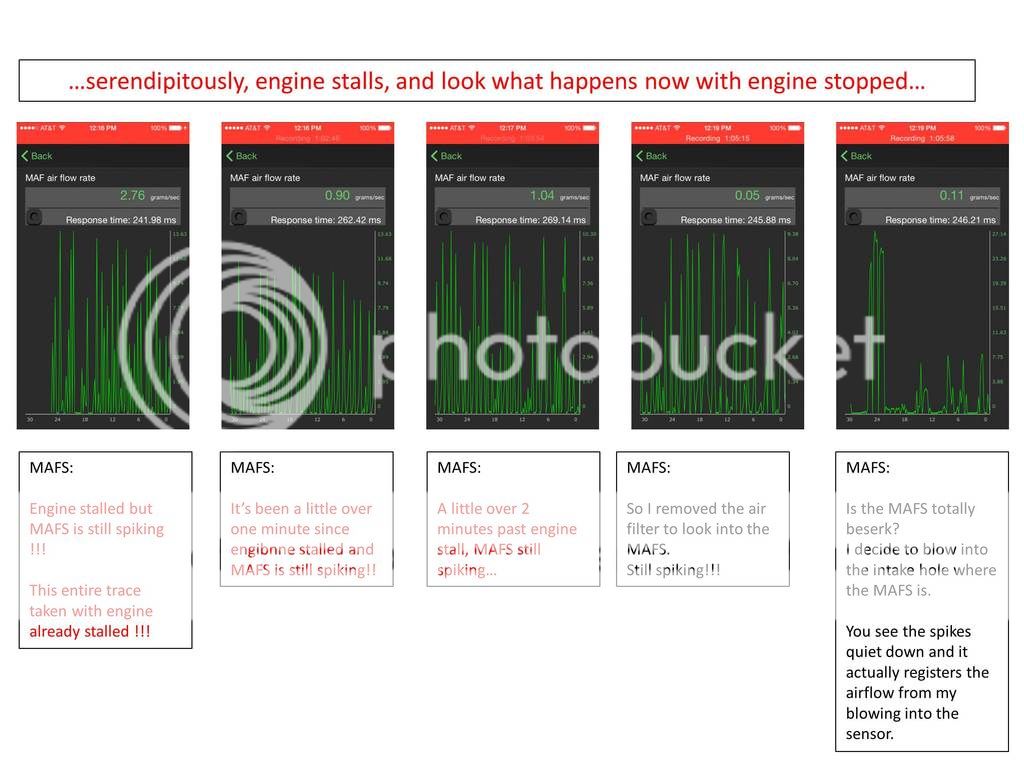

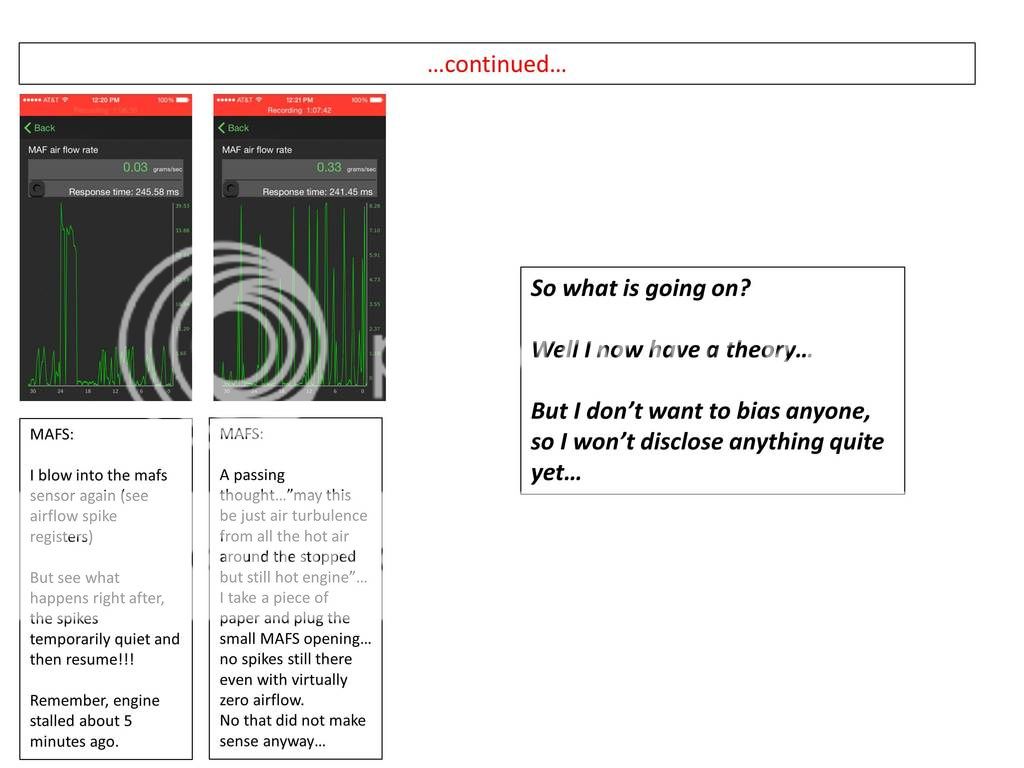

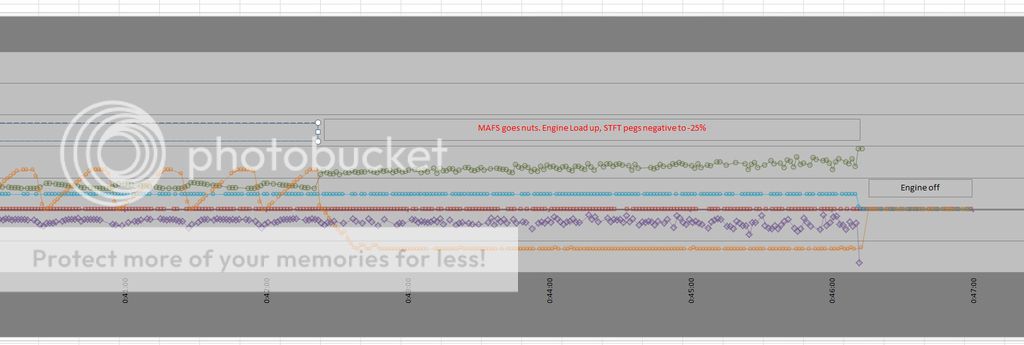

Concerned about the 200+ mile return trip, I took truck to only garage I found open. Very nice guy, pleasant to work with and seemed competent. After running diagnostics he said the MAF signal was noisy and that Nissan had a TSB about adding an additional ground wire to the MAF sensor. He put the extra ground but things did not improve. So he said it was the electrical connector to the MAF that was faulty (logical). He actually demonstrated to me how with the engine on idle, pressing on the MAF electrical connector caused the engine to stall. Not sure how many times he tried that and whether it might have been a coincidence. Unable to find a connector on Sunday, he tried to fix it by bending a bit the pins and when that did not work trying to insert small wires in the connector to achieve better contact, but that did not work either.

At this point I started suspecting that indeed the problem might be at the MAF but not with the connector. Rather with the MAF itself. I thought it was more logical that the pressure he was applying to the connector somehow transferred inside the MAF and that is where the problem is. Otherwise, I could not see how a marginal connector can be disassembled two, three, five times and always get that marginal connection. Typically futzing with a marginal connector at all makes it either establish contact or drop contact completely. And dropping contact completely would have caused a code (I had tested that myself, removing the MAF connector threw the expected P0100 code and set the computer in safe mode with intentional fuel cutoff above 2000RPM).

In any case, he was not able to fix it, but I successfully made the 200+ mile trip back home, with just one stall on idle at stoplights and about ten “hiccups” at freeway speeds. Otherwise, engine behavior was, I would say, normal, or perhaps near normal overall.

BTW, the mechanic was very nice. I wanted to pay him at least something for the 1.5 hours he spent working on my truck, even if he did not ultimately fix it, but he insisted that he did not want any money since he was unable to fix it. So I left feeling kind of bad -- I thought I should at least buy him a gift next time I go by that area (which I tend to do once a month).

In any case, now that I’m back home I’d like to see if I can fix this problem, so before I do anything I wanted to ask,

Anyone else had similar issues or insights?

A couple of other things I noticed:

No engine light and no codes

Took the spark plugs out on my first diagnostic attempt and they were all 4 darker than usual, not wet but with more carbon than usual. Right before I took spark plugs out truck had been idling for a while and then had stalled by itself. I did not try to look at spark plugs after a normal drive.

Even when the engine is not stalling on idle, the idle speed is sometimes a little erratic, but not always.

Malfunction may be more prominent in hot desert air than cooler moist air. But it’s a rather recent problem, so I’m not sure, could be coincidence.

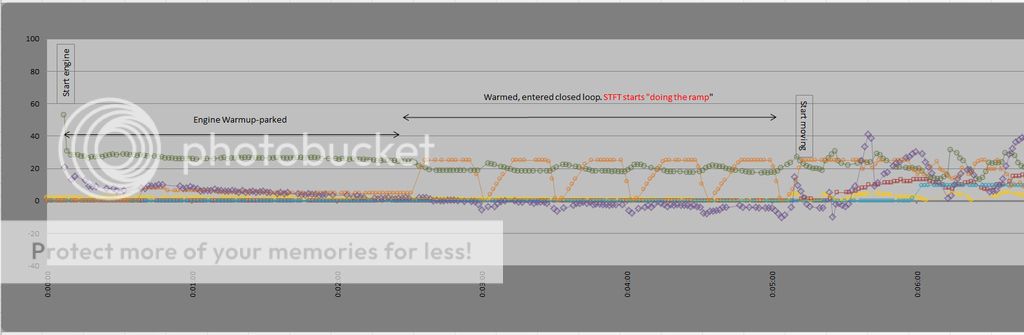

Starts fine and no problems while engine cold. Any intermittent problems only start after engine has warmed up.

The stall is most repeatable when I rev up engine in neutral and then release the gas and let it go to idle. That is when it typically stalls.

Sometimes as the idle RPM drops below normal, it revs up and recovers.

Fast idle when cold works as expected- also higher RPM when AC on also works as expected

I moved around spark plug wires several times while engine was idling, no difference

I looked at the MAF sensor, looks clean

I intentionally disconnected MAF to see if problem would go away in computer safe mode. Did not completely stall but engine operation without MAF was quite erratic, rough idle and not able to go above 2200 rpm (I think this is expected since computer goes into safe mode). But erratic behavior makes it hard to come to conclusions. I did get the P0100 code disconnecting the MAF, so some error detection is working.

I looked at the IACV (Idle Air Control Valve). I can hear it clicking when I disconnect and reconnect it while ignition on and engine off. Measured correct solenoid resistance ( 10.9ohms). Got the correct codes (P505) when I disconnected it for more than a couple of seconds.

I noticed that the IACV solenoid buzzes just a tad bit with ignition on and engine not running (when everything is quiet). But not a loud buzzing.

My speedometer is sometimes acting funny, showing higher or lower speed than normal (+-20 mph), but this has been going on for quite a while (a year or so) and seems to be unrelated to this stalling problem. Definitely predates it by a long shot.

No other prior major problems. Though a 4 banger I love the truck, has served me well. I maintain it well – myself. Yes, I have had the typical O2 sensor going bad here and there and a couple of minor coolant leaks from 15+ year hoses, all expected.

Thanks for reading.

Any advice appreciated.

As of 4 days ago I’ve had occasional stalling on idle (perhaps 1 out of 10 times I stop at a stoplight) and also occasional very brief engine hesitations at cruising speeds, akin to a, say, brief “hiccup” in engine power (perhaps a dozen episodes in a 250 mile trip).

It first happened 200 miles away from home on my 4th of July trip. Not a good situation.

No engine light and no codes (I read them).

Concerned about being left stranded, I tried to debug the thing myself since everything was closed for 4th of July. Ended up suspecting the IACV (Idle Air Control Valve) as something that would likely result in this behavior and would also likely not generate a code. But I did not get anywhere. I just sprayed some carburetor cleaner in the throttle air bypass hole, which seemed to make things a little worse, as it seemed to be stalling more often – but it could have been the higher engine temperature too, after repeated starts. Taking apart to clean the IACV was out of the question since I was going to have to remove the throttle body and did not have spare seals to reassemble (seals would likely rip on disassembly after 17 years).

Concerned about the 200+ mile return trip, I took truck to only garage I found open. Very nice guy, pleasant to work with and seemed competent. After running diagnostics he said the MAF signal was noisy and that Nissan had a TSB about adding an additional ground wire to the MAF sensor. He put the extra ground but things did not improve. So he said it was the electrical connector to the MAF that was faulty (logical). He actually demonstrated to me how with the engine on idle, pressing on the MAF electrical connector caused the engine to stall. Not sure how many times he tried that and whether it might have been a coincidence. Unable to find a connector on Sunday, he tried to fix it by bending a bit the pins and when that did not work trying to insert small wires in the connector to achieve better contact, but that did not work either.

At this point I started suspecting that indeed the problem might be at the MAF but not with the connector. Rather with the MAF itself. I thought it was more logical that the pressure he was applying to the connector somehow transferred inside the MAF and that is where the problem is. Otherwise, I could not see how a marginal connector can be disassembled two, three, five times and always get that marginal connection. Typically futzing with a marginal connector at all makes it either establish contact or drop contact completely. And dropping contact completely would have caused a code (I had tested that myself, removing the MAF connector threw the expected P0100 code and set the computer in safe mode with intentional fuel cutoff above 2000RPM).

In any case, he was not able to fix it, but I successfully made the 200+ mile trip back home, with just one stall on idle at stoplights and about ten “hiccups” at freeway speeds. Otherwise, engine behavior was, I would say, normal, or perhaps near normal overall.

BTW, the mechanic was very nice. I wanted to pay him at least something for the 1.5 hours he spent working on my truck, even if he did not ultimately fix it, but he insisted that he did not want any money since he was unable to fix it. So I left feeling kind of bad -- I thought I should at least buy him a gift next time I go by that area (which I tend to do once a month).

In any case, now that I’m back home I’d like to see if I can fix this problem, so before I do anything I wanted to ask,

Anyone else had similar issues or insights?

A couple of other things I noticed:

No engine light and no codes

Took the spark plugs out on my first diagnostic attempt and they were all 4 darker than usual, not wet but with more carbon than usual. Right before I took spark plugs out truck had been idling for a while and then had stalled by itself. I did not try to look at spark plugs after a normal drive.

Even when the engine is not stalling on idle, the idle speed is sometimes a little erratic, but not always.

Malfunction may be more prominent in hot desert air than cooler moist air. But it’s a rather recent problem, so I’m not sure, could be coincidence.

Starts fine and no problems while engine cold. Any intermittent problems only start after engine has warmed up.

The stall is most repeatable when I rev up engine in neutral and then release the gas and let it go to idle. That is when it typically stalls.

Sometimes as the idle RPM drops below normal, it revs up and recovers.

Fast idle when cold works as expected- also higher RPM when AC on also works as expected

I moved around spark plug wires several times while engine was idling, no difference

I looked at the MAF sensor, looks clean

I intentionally disconnected MAF to see if problem would go away in computer safe mode. Did not completely stall but engine operation without MAF was quite erratic, rough idle and not able to go above 2200 rpm (I think this is expected since computer goes into safe mode). But erratic behavior makes it hard to come to conclusions. I did get the P0100 code disconnecting the MAF, so some error detection is working.

I looked at the IACV (Idle Air Control Valve). I can hear it clicking when I disconnect and reconnect it while ignition on and engine off. Measured correct solenoid resistance ( 10.9ohms). Got the correct codes (P505) when I disconnected it for more than a couple of seconds.

I noticed that the IACV solenoid buzzes just a tad bit with ignition on and engine not running (when everything is quiet). But not a loud buzzing.

My speedometer is sometimes acting funny, showing higher or lower speed than normal (+-20 mph), but this has been going on for quite a while (a year or so) and seems to be unrelated to this stalling problem. Definitely predates it by a long shot.

No other prior major problems. Though a 4 banger I love the truck, has served me well. I maintain it well – myself. Yes, I have had the typical O2 sensor going bad here and there and a couple of minor coolant leaks from 15+ year hoses, all expected.

Thanks for reading.

Any advice appreciated.